|

Scientific Paper / Artículo Científico |

|

|

|

|

https://doi.org/10.17163/ings.n32.2024.02 |

|

|

|

pISSN: 1390-650X / eISSN: 1390-860X |

|

|

STRUCTURAL EVALUATION OF A THREE-WHEELER VEHICLE USING SIMULATION

TOOLS: A CASE STUDY IN MEXICO |

||

|

EVALUACIÓN ESTRUCTURAL DE UN VEHÍCULO TIPO MOTOTAXI USANDO HERRAMIENTAS DE SIMULACIÓN: CASO MÉXICO |

||

|

Received: 14-05-2023, Received after review: 28-03-2024, Accepted:

23-04-2024, Published: 01-07-2024 |

|

Abstract |

Resumen |

|

The mototaxi, a three-wheeled vehicle equipped with a roof,

is a widely utilized mode of transportation in Mexico. Typically, it is

employed for short-distance journeys in exchange for payment, similar to the operation of a conventional taxi. This

study conducts a structural analysis of a mototaxi-type

vehicle utilized in Mexico to assess its performance and safety. It

underscores the significance of this mode of transportation, widely relied

upon by numerous individuals. A product design and development methodology was employed, utilizing torsional deformation simulations

to validate the new geometry. The objective was to minimize torsions as much

as possible, thereby enhancing the motorcycle taxi’s safety and ensuring the

vehicle’s correct positioning. Through computeraided

design, the prevailing torsions within the casing were assessed, establishing

the operating conditions to which the system is commonlysubjected.

The findings from the chosen vehicular structure reveal a flexural rigidity

of 6,508.15 N/mm, torsional rigidity of 27.35 KNm/º,

and a range of natural frequencies between 8-21 Hz. These values indicate

favorable resistance against bending forces and operational frequency.

However, the torsional results exhibit deficiencies, suggesting an unsafe

structure for all motorcycle taxi occupants. Consequently, technology

developers and national legislators should prioritize enhancing the

structural integrity of such vehicles. |

El mototaxi es un vehículo de tres ruedas y con techo que se usa como medio de transporte popular en México, generalmente para recorrer caminos cortos a cambio de dinero, de la misma forma que opera un taxi. Esta investigación presenta el análisis estructural de un vehículo tipo mototaxi empleado en México, para evaluar su desempeño y seguridad, teniendo en cuenta que es un medio de transporte utilizado por muchas personas. Se empleó una metodología de diseño y desarrollo de producto, utilizando simulaciones de deformación torsionales para validar la nueva geometría, minimizando las torsiones en lo posible, tratando de mejorar la seguridad del mototaxi, así como la posición correcta del vehículo. Mediante el diseño asistido por computadora se probaron las torsiones existentes en la carcasa, determinando las condiciones de operación por las que generalmente es sometido el sistema.Los resultados obtenidos en la estructura vehicular seleccionada son para la rigidez por flexión de 6508,15 N/mm, la rigidez torsional de 27,35 KNm/º y el rango de frecuencias naturales en 8-21 Hz, valores que muestran que la estructura presenta condiciones favorables mediante esfuerzos de resistencia por flexión y la frecuencia de operación de la estructura, pero carencias en los resultados torsionales, generando así una estructura insegura para los ocupantes del mototaxi. Es necesario que los desarrolladores de tecnología como los legisladores nacionales actúen en favor de mejorar sus condiciones estructurales. |

|

Keywords: Structural, mototaxi,

safety, ANSYS, CAE, simulation |

Palabras clave: estructural, mototaxi, seguridad, ANSYS, CAE, simulación |

|

1,*Facultad de Ingeniería

Industrial, Logística, Manufactura y Automotriz, Universidad Popular Autónoma

del Estado de Puebla, México.Corresponding author ✉: josejesus.cordero@upaep.mx. 2Benemérita

Universidad Autónoma de Puebla – México. Suggested citation: Cuautle Gutiérrez, L.; Cordero Guridi, J. J.; Olivares Rojas, J. E. and Pena Preza, N. “Structural Evaluation of a Three-Wheeler Vehicle Using Simulation Tools: A Case Study in Mexico,” Ingenius, Revista de Ciencia y Tecnología, N.◦ 32, pp. 18-26, 2024, doi: https://doi.org/10.17163/ings.n32.2024.02. |

|

1.

Introduction The insufficient

supply and restricted public transportation coverage in developing countries

have prompted the emergence of mototaxism in

numerous cities worldwide, wherein motorcycles are utilized as a form of

public transportation. A

mototaxi, characterized by its three-wheeled

structure and roof, is a cost-effective means for individuals to fulfill

their mobility requirements, akin to traditional taxis. It fills a unique

niche in transportation services, catering to entire journeys and the initial

and final segments of trips in densely populated, congested, or otherwise

inaccessible areas. These trips are often too lengthy and challenging to

traverse by foot yet fall short of commercial viability for conventional

public transportation modes. The

inception of the mototaxi occurred in Paris in

1999, representing an innovative and efficient transportation solution aimed

at addressing the travel requirements of passengers commuting between the

city’s two airports [1]. For

approximately two decades, this mode of transportation has been present in

Mexico City and various states of the Republic, predominantly in the form of

motorcycles equipped with a canopy and cabinincorporated

motocarros [2]. The

mototaxi caters to particular yet

unfulfilled transportation demands and functions more as a supplementary

service than a direct competitor to other public transportation modes. Its

primary advantage lies in its lightweight construction, speed, and ease of

parking, enabling users to traverse short distances more efficiently.

According to the National Institute of Statistics and Geography, over 273,000

mototaxi trips occur daily in Mexico City and its

metropolitan region, constituting 3.7% of all public transportation. journeys

[3]. In

Juchitán de Zaragoza, Oaxaca, Mexico, the King

model is frequently employed as a mototaxi owing to

its versatile chassis, instrumentation, engine, power, and torque

capabilities. This model achieves a maximum speed of 56 kilometers per hour

and has a curb weight of 300 kilograms [4]. Mototaxis belong to the classification of small motor

vehicles, alongside mopeds, scooters, motorcycles, motorized tricycles, quad

bikes, and analogous vehicles [5]. The

mototaxi industry grapples with numerous

challenges, encompassing congestion, road infrastructure, regulatory

standards, and safety considerations [6]. |

On a global scale, the utilization of mototaxis has adversely affected the environment, social

dynamics, and road safety. The adverse environmental impacts primarily

stem from pollutant emissions resulting from inadequate vehicle maintenance

and the use of low-quality fuel [7]. In the State of Mexico, mototaxis

serve as sources of informal employment for both men and women, offering an

average weekly income of $1236 to drivers. These drivers typically possess a

secondary or high school education, with common-law marriage being the most

prevalent marital status [8]. Puebla has over ten thousand estimated mototaxi drivers across over sixty municipalities [9]. Regarding road safety issues, mototaxis are responsible for numerous severe traffic

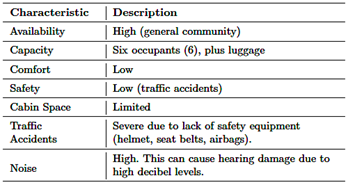

accidents. Table 1 presents some characteristics of

these vehicles that highlight the safety issues associated with them. Table 1. Characteristics of Mototaxis

Moreover, the chassis is commonly regarded as

the vehicle’s skeleton, as it accommodates the components necessary for

proper operation. The chassis must possess sufficient strength to withstand

impacts, torsion, vibrations, and other stresses encountered during

operational activities. Another crucial aspect concerns legislation,

as all vehicles operating on public roads must adhere to specific regulations

established by some institutions and laws. In numerous Mexican states, mototaxis remain largely unregulated. However, in the

state of Puebla, guidelines governing mototaxis are

outlined in the transportation law, particularly in articles 12 and 37 [10]. Hence, this study aims to assess the

structural integrity of this mode of transportation to ascertain the level of

safety provided by service providers to their users. |

|

2.

Materials and

method A product design and

development methodology was employed to assess the

performance and safety of the mototaxi-type

vehicle, utilizing a digital model of the three-wheeled vehicle structure.

The study proceeded through the following phases: benchmarking, technical

characterization, development of the analysis model, and structural

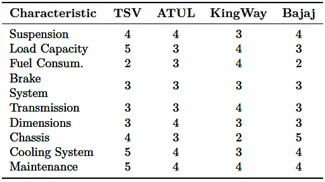

evaluation. Four

prominent brands in Mexico, including TSV, ATUL, KingWay,

and Bajaj and their primary models were examined during the benchmarking

phase. Eight key characteristics were analyzed, including maximum power,

maximum torque, fuel consumption, load capacity, brakes, chassis, and

stabilizer bar, as detailed in Table 2. Table 2. Evaluation of Mototaxi Brands

Using

the acquired data, each vehicle underwent an evaluation to ascertain the one

possessing superior attributes. In this subsequent phase, nine

characteristics were considered as delineated by the authors. Ratings were

assigned on a 5-point scale, with 1 representing deficiency and 5 indicating

optimal performance, as outlined in Table 2. The TSV brand, specifically the

King Duramax model, attained the highest score. The

ratings were determined through consensus among the authors. Based on the averaged scores, the King Duramax was selected with a

rating of 3.71. It is noteworthy that the results were closely aligned, as

the four models under scrutiny exhibited very comparable characteristics and

performance, thereby sharing similar attributes. In

the technical characterization, the TVS Group, an Indian company ranking

third globally, is India’s largest manufacturer of two-wheeled vehicles, with

its products being exported to over sixty countries. Renowned for delivering

high-quality vehicles that cater to customer requirements, TVS has

established Motocarros TVS in Mexico. This branch,

dedicated to the distribution of three-wheeled vehicles, operates under

Kawasaki with the backing of Grupo Motomex. The

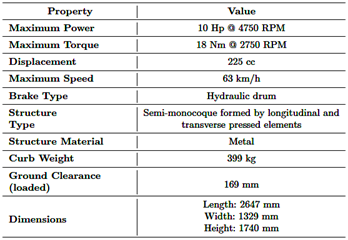

selected unit was the King Duramax 2020, shown in Figure 1. |

Based on the obtained data, each vehicle was

rated to determine the one with the best qualities. For this new stage, nine

characteristics defined by the authors were considered. The ratings were on a

5-point scale where 1 is deficient and 5 is optimal, as presented in Table 2.

The highest score was obtained by the TSV brand, with the King Duramax model. The ratings were assigned by consensus among

the authors. According to the averages obtained, the King Duramax was chosen

with a score of 3.71. It is important to mention that the results were very

close because the four analyzed models have very similar characteristics and

performance, thus having similar elements. In the technical characterization, the TVS

Group, an Indian company that ranks third, is the largest manufacturer of

two-wheeled vehicles in India, currently exporting to more than sixty

countries. It is a company known for offering quality vehicles that

anticipate customer needs. In Mexico, Motocarros

TVS, the branch dedicated to the commercialization of three-wheeled vehicles,

is part of Kawasaki with the support of Grupo Motomex. The chosen unit was the King Duramax 2020, as

illustrated in Figure 1.

Figure 1. King Duramax 2020 [11]. Table 3 presents some of its technical

features. Table 3. Technical

Characteristics of the King Duramax 2020

|

|

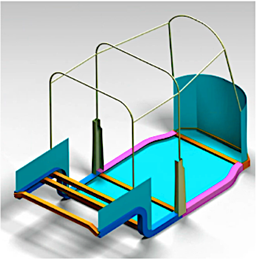

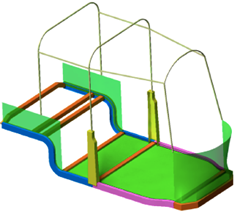

During

the development stage of the CAD analysis model, CAD and CAE software,

including CATIA V5 2020 and Ansys 2020, were utilized. A

similar configuration model was proposed using the data collected from the mototaxi benchmarking. It comprised a semi-monocoque

structure constructed from longitudinal and transverse pressed elements,

commonly referred to as a ladder frame or chassistype

structure, as depicted in Figure 2.

Figure 2. Ladder or Chassis Type

Automotive Structure Considering

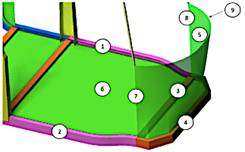

the information from the TVS manufacturer, a model comprising 30 components

was developed. These components primarily encapsulate those pertinent and

indispensable for analysing the vehicle’s

structure, including chassis elements, lower panels, and select exterior

panels, as depicted in Figure 3.

Figure 3. CAD Model of the Structure Figure

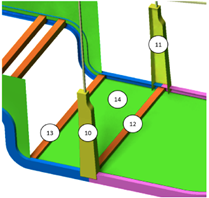

4 depicts the structure’s frontal components, featuring the removal of the

front panel to expose the chassis components and panels. |

Figure 4. Front Chassis

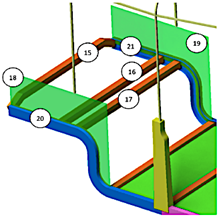

Elements Figure 5 illustrates the intermediate

elements of the vehicle, highlighting the "posts" and components

responsible for supporting the passengers.

Figure 5. Intermediate

Chassis Elements Figure 6 illustrates the rear section of the

structure with the components that accommodate mechanical elements like the

engine system and rear suspension, along with the rear panels and the rear

impact bar.

Figure 6. Rear Chassis Elements |

|

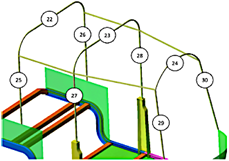

Furthermore,

additional minor pertinent elements were included in the vehicle evaluation,

characterized by a roof structure possessing the following properties, as

illustrated in Figure 7.

Figure 7. Estructura superior del techo Ultimately,

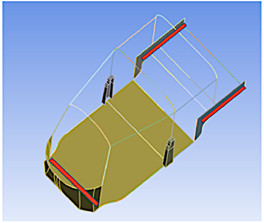

Figure 8 displays the final model intended for structural analysis. This

model exclusively incorporates the elements utilized in the CAE evaluation of

the vehicle.

Figure

8.

Global View of the Mototaxi Model for Structural

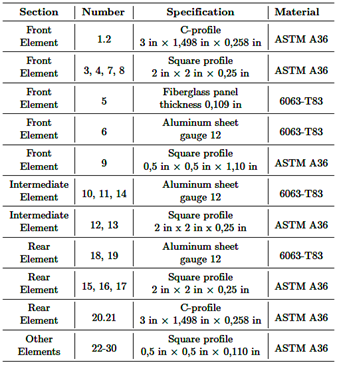

Evaluation Table

4 presents the various components utilized along with their descriptions,

particularly regarding the type of profile employed for structural

evaluation. For

the vehicle evaluation, several materials were initially explored for the

modeled elements to ensure optimal outcomes. ASTM A36 steel and 6063-T83

aluminum alloy were chosen for their established applications in automotive

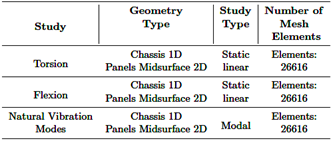

structures and panels [12]. Considering this, three studies were proposed using ANSYS software to assess torsional rigidity, flexural rigidity, and natural vibration modes. The pertinent global variables are outlined in Table 5. |

Table

4.

Specification of Selected Components in the Mototaxi

Structure

Table 5. Technical

Specification of Considered Global Variables

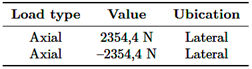

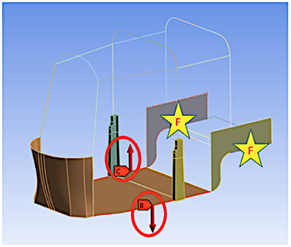

Figure 9 illustrates the applied constraints

(depicted by stars labeled with the letter F) and the utilized loads (vectors

identified with annotations B and C inside circles) for the torsion analysis

of the structure, along with the obtained deformation values. The load values

were determined by prioritizing loads that closely mimic real-world

conditions, as specified in Table 6. Table 6. Specification of Load

Locations on the Primary Structure of the Mototaxi

for Study

|

|

Figure

9.

Global View of the Mototaxi Model Representing

Applied Loads for Study Given

the possibility of mototaxi operators occasionally

overloading the structure, it is imperative to ascertain its resistance to

torsional forces. Consequently, investigations were conducted using a maximum

load capacity of six individuals, each weighing an average of eighty kilograms,

resulting in a total of 4708 N, distributed in two sections. These revised

values were then applied to the lateral areas of the mototaxi

structure in opposite directions to assess and validate the newly acquired

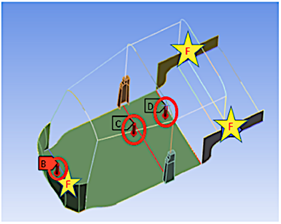

results. Figure

10 illustrates the applied constraints (depicted by stars labeled with the

letter F) and the utilized loads (directional vectors annotated with B, C,

and D enclosed in circles) for the flexural analysis of the structure, from

which deformation values are derived.

Figure 10. Constraints in

the Flexural Analysis For

the flexural analysis, the maximum load capacity that the primary structure

can sustain was considered, amounting to seven individuals, each averaging

eighty kilograms. Consequently, with a total load of 560 kilograms, this

value is distributed among the three beams depicted in the figure, resulting

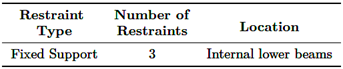

in a distribution of 5494 N among the three beams represented. For the modal study, the analysis focused on examining the six natural vibration modes of the model. Figure 11 illustrates the positional constraints applied to |

the vehicle structure for this analysis. Table 7 specifies the type of

restraints employed in the study.

Figure 11. Positional

Constraints Table 7. Specification of Load

Locations on the Primary Structure of the Mototaxi

for Study

3.

Results and

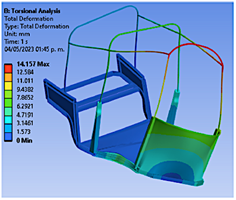

Discussion Figure 12 illustrates the torsional deformation induced by the

previously described loads.

Figure 12. Global View of the Mototaxi Model Representing the Results of Torsional

Loads As depicted in Table 8, a torsional rigidity value of 27.35 KNm/º was derived from the applied torsional load and a measured structural torsion angle of 0.27251°. Furthermore, the maximum observed deformation amounts to 14.157 mm.

|

|

Table 8. Torsional Evaluation

Results

For

flexural rigidity, Figure 13 depicts the observed deformationin

the mototaxi structure.

Figure

13. Global View of the Mototaxi Model

Representing the Results of Flexural Loads The

maximum observed deformation is 0.84424 mm, leading to a flexural rigidity

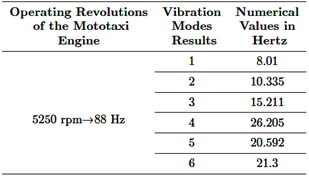

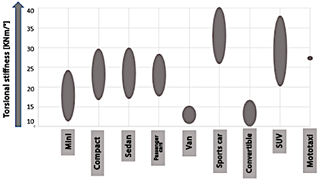

value of 6508.15 N/mm. As for the modal analysis of the mototaxi

structure, Figure 14 illustrates the various vibration modes of the analyzed

structure. As part of this assessment, the typical engine operating

revolutions of the vehicle were identified, with an operational frequency

determined to be 88 Hz. In

Table 9, the numerical values found in the vibration modes of the structure

are described. Table 9. Modal Evaluation

Results

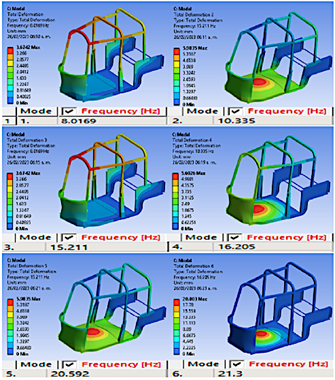

To

ascertain the suitability of the acquired torsion and flexion values for the

analyzed structure, the comparison by Hirz was employed

as a reference. This comparison encompasses nine distinct categories,

detailing specific ranges of torsional stresses for each category [13]. |

Figure 14. Global View of the Mototaxi Model Representing the Results of Applied Loads

for Study In the analysis of the mototaxi,

the categories primarily considered were "mini car," "compact

car," and "convertible," facilitating a comparable assessment.

Particular emphasis was placed on the

"convertible" category due to the mototaxi’s

configuration. Given its structural design primarily in the lower part, it

bears a strong resemblance to the "convertible" category. Based on the analysis depicted in Figure 15,

it is evident that the structure exhibits greater torsional rigidity compared

to the "convertible" category, which typically ranges from 10 to 17

KNm/º, while the mototaxi

demonstrates a value of 27.35 KNm/º. As for

flexural rigidity, a similar comparison was conducted with analogous

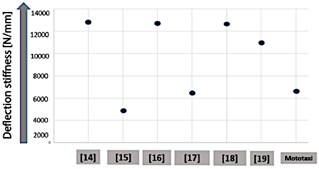

structures from diverse studies, and Figure 16 displays six different studies

[14–19] along with their respective values.

Figure 15. Comparison of

Structural Torsion Resistance Results |

|

Figure 16. Comparison of Flexural

Rigidity Results When

comparing flexural stresses, it is evident that the mototaxi

structure exhibits a value of 6508.15 N/mm. The reviewed studies reveal

comparable values, suggesting that the structure behaves similarly (with

values ranging from 5 to 13 KN/mm) to other studies evaluatingflexural

rigidity. 4.

Conclusions The

conducted studies comprehensively assessed the performance of the vehicle

structure across three primary criteria: flexural rigidity, torsional

rigidity, and modal evaluation. The meticulous analysis of the calculated

values and comparisons revealed that the mototaxi-type

structure exhibits notable concerns regarding structural integrity. These

concerns were underscored by observable deviations compared to similar

structures in the vehicle’s torsional studies. This discrepancy hints at

potential structural behavioral issues during operation, possibly stemming

from the absence of an integrated structure, including the roof. Consequently,

this deficiency impairs the structure’s performance efficiency, diminishing

energy absorption and dissipation capacity. Notably, the flexural studies of

the structure yielded values closely aligned with those of comparable

structures. In contrast, the modal evaluation revealed a lack of alignment

between the natural frequencies and the operational frequency of the

vehicle’s components, thus indicating inadequacies under these criteria. Similarly,

A. Rodríguez [20] analyzed a tricycle structure under defined parameters and

specified load cases. Unlike the aforementioned studies,

which primarily focused on assessing the structure’s failure and fatigue

criteria, this investigation focused on evaluating the vehicle’s response

under static working conditions. Future work could encompass evaluations

incorporating relevant failure criteria and dynamic behavior analyses,

thereby addressing potential |

hazards associated with frontal and lateral

collisions or rollovers. While vehicles of this class were primarily

developed to provide an economical mobility option for both users and

operators, the structure of mototaxis poses risks

to the safety of passengers. It is imperative for local and national

legislation, as well as developers of this vehicle technology, to enhance its

structural and dynamic conditions. References

[1] B. A. A. López, N. D. L. Ledón, J. A. González, and J. E. D. Reinoso, “Mototaxis como medio de transporte público en el municipio de San Blas, Nayarit,” Universo de la Tecnología, vol. 1, no. 43, pp. 25–31, 2023. [Online]. Available: https://bit.ly/3UoAe9Q [2] N. Ortuya.

(2023) Mototaxi en méxico: ¿una buena alternativa

de trnasporte? Autofact. Autofact.

[Online]. Available: https://bit.ly/3QoFold [3] M. Sánchez. (2019) Están prohibidos, pero los mototaxis llevan a la gente a donde tiene que ir. Global Press Journal. Global Press Journal. [Online]. Available: https://bit.ly/3JGoRFi [4] M. J. Solís, C. A. López, and R. Gómez, “El mototaxi como medio de transporte público en Juchitán de Zaragoza, Oaxaca,” Centro Educativo Cruz Azul, 2016. [Online]. Available: https://bit.ly/3WghKuR [5] DRTCSanMartin, Manual del conductor, Capítulo 6: El Vehículo. Dirección Regional de Transportes y Comunicaciones de San Martín. Perú, 2021. [Online]. Available: https://bit.ly/4aUO9vz [6] Z. J. Chan, V. Hung, and K. Kallmyer, Inclusión social y movilidad: el sector del mototaxi en Tarapoto (Perú), 2019. [Online]. Available: https://bit.ly/44mbsvA [7] L. Diaz Olvera, D. Plat, P. Pochet, and M. Sahabana, “Un transporte urbano no convencional en áfrica subsahariana: el mototaxi,” Revista VIAL, pp. 52–54, 01 2011. [Online]. Available: https://bit.ly/3QCLgr8 [8] J. L.

Bernal López, “El autoempleo en el transporte informal como forma de exclusion social: el caso de los mototaxistas del

municipio de chimalhuacán,” Análisis económico,

vol. 36, no. 93, pp. 141–158, 2021. [Online]. Available: https://doi.org/10.24275/uam/azc/dcsh/ae/2021v36n93/Bernal [9] B. Barrios Hernández and P. F. Coutiño Osorio, “El servicio de mototaxis: una fuente alternativa de trabajo en Puebla,” DIKE, no. 15, pp. 157–171, 2014. [Online]. Available: http://dx.doi.org/10.32399/fder.rdk.25940708.2014.15.168 |

|

[10] Congreso de Puebla, Ley de movilidad y transporte del Estado de Puebla. Honorable Congerso del Estado de Puebla, 2021. [Online]. Available: https://bit.ly/4a5ZxDn [11] MSM, Ficha técnica: Motor de encendido por chispa de 4 tiempos,

refrigerado por liquido. Moto Soluciones

México, 2023. [Online]. Available: https://bit.ly/3JQSAvl [12] C. Okpala, T. Nwokeocha, L. Ofuoku, A. Akajiugo, and J. Adonu, “Design

and analysis of chassis and spring of a load- bearing tricycle,”

International Journal of Advanced Engineering Technology, vol. 8, no. 3, pp.

10–15, 2017. [Online]. Available: https://bit.ly/3WxEbMi [13] M. Hirz. (2016)

What are the typical stiffness values while designing car chassis?.

ReserachGate. ReserachGate.

[Online]. Available: https://bit.ly/3wqmMKC [14] D. Fang and W. Kefei, “Simulation analysis and experimental verification

on body-in-white static stiffness of a certain commercial vehicle,” Vibroengineering PROCEDIA, vol. 29, pp. 141–147, nov 2019. [Online]. Available: https://doi.org/10.21595/vp.2019.21171 [15] H. J. Yan, X. Liu, G. Q. Zhao, N. Tian, and S. K. zhang, “Analysis and Research of Stiffness Based on Body-in-White NVH,” Journal of Physics: Conference Series, vol. 1087, no. 4, p. 042078, sep 2018. [Online]. Available: https://dx.doi.org/10.1088/17426596/1087/4/042078 |

[16] Z. Wentao,

W. Zhenhu, F. Xiangdong,

Y. Xuyue, L. Luoxing, and

W. Wanlin, “A calculation method of car body in

white’s static stiffness based on modal theory,” China Mechanical

Engineering, vol. 29, no. 5, pp. 511–518, 2018. [Online]. Available: https://bit.ly/4a7wkYN [17] C. Hartmann, M. Welm, S.

Schreyer, C. Hartmann, and W. Volk, “A modular car body for sustainable,

cost-effective, and versatile vehicle development,” Technologies, vol. 9, no.

1, 2021. [Online]. Available: https://doi.org/10.3390/technologies9010013 [18] M. H. Shojaeefard,

A. Khalkhali, M. Sarmadi,

and N. Hamzehi, “Investigation on the optimal

simplified model of BIW structure using FEM,” Latin American Journal of

Solids and Structures, vol. 12, no. 10, pp. 1972–1990, Oct 2015. [Online].

Available: https://doi.org/10.1590/1679-78251923 [19] M. M. Shivakumar and L.

Nirmala, “Fatigue life estimation of chassis frame fesm

bracket for commercial vehicle,” International Journal of Science and

Research (IJSR), vol. 3, no. 8, pp. 441–447, 2014. [Online]. Available: https://bit.ly/4brALP9 [20] A. Rodríguez, B. Chiné, J. A. Ramirez, and Costa, “Finite element modeling of an aluminum tricycle frame,” 2016. [Online]. Available: https://bit.ly/4aqmFwR |